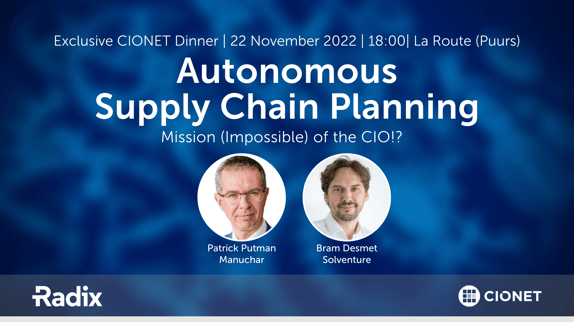

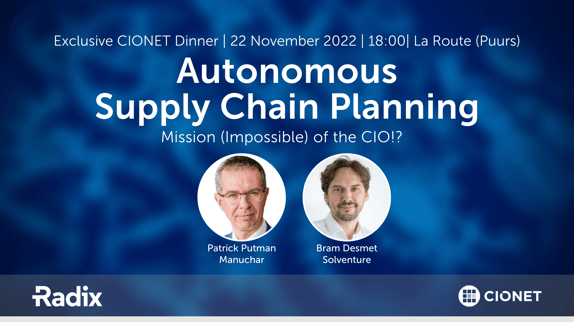

We met on Tuesday evening, November 22, at “La Route”. What was once a farmers’ barn next to a century-old railroad is today a beautifully renovated restaurant where chef Mathieu serves French cuisine inspired dishes. Our fellowship consisted of ten digital leaders invited by CIONET and its partner, RADIX. The theme of the evening is next-generation supply chain planning or how AI can turn supply chain planning into an autonomous system that responds to contemporary challenges.

But what are these main challenges regarding supply chain planning? The ‘tour de table’ among all participants raised several common concerns. How can one bring operational and financial planning together? How can one make reliable forecasts while dealing with volatile markets, variable demand and unpredictable raw material pricing? How to tame the complexity of a fast-growing group and turn supply chain planning into a single, clear and manageable end-to-end flow? And while doing so, how can you avoid technical debt, quickly installing systems or software typically with the purpose of rapid gains that could take more work to fix at a later time?

Supply chain planning is, by definition, a strenuous exercise as one needs to predict for the longest

possible period, on the one hand, what the production units need and what the customers will buy

and, on the other hand, when and what suppliers will deliver. Warehouses must be emptied on time to store newly arriving goods, for instance, by launching sellouts with reduced pricing. For some companies – especially those trading significant volumes - a minor adjustment of these predictions can stand for major capital wins or losses.

Moreover, proper supply chain planning has become a big challenge today as geopolitical tensions are causing unprecedented pressure on the global supply of energy, (raw) materials and technical components. Companies are decreasing their dependencies on too few (global) suppliers and go local, thus making their supply chains less vulnerable but more complex with multiple layers and scenarios.

One of the critical issues is the lack of exchange and reliability of the different players' data in the supply chain. Companies, especially their supply chain teams, often have to be very creative in

covering the missing information. They use various means and build their algorithms, to calculate the capacities of boats, trains or trucks and predict when products will "probably" get delivered. That is great, but it is also wrong as it removes the burning platform to address the necessary investments and operational change programmes.

-1.png?width=751&height=278&name=BE%20Newsletter%20Content%202022%20(12)-1.png)

Anyhow, the challenges supply chain planning is confronted with nowadays are still in sharp contrast to the observation that supply chain planning is often still largely neglected in terms of IT

investments, capabilities and top management attention. In some companies, even a basic data

backbone on which data and processes are aligned is still missing, and supply chain planning remains the black box of some talented creative experts. This is a critical situation, considering the growing challenge and impact of supply chain planning for the business.

That brings us to the question of whether there is a major challenge and opportunity for AI in the

domain of supply chain planning. And, as one of the guests was questioning: is it AI we need or

machine learning?

AI is often confused with machine learning, as to Laurent Sorber, CTO and co-founding father of

Radix. AI encompasses Machine Learning, next to other technologies. In the context of supply chain planning, AI must be seen as cognitive automation: the automation of tasks and processes with some level of intelligence. It represents a spectrum of approaches that improve how automation can capture data, automate decision-making and scale automation. At the same time, machine learning is based on ‘learning by example’, a concept that needs loads of data to feed a learning process, a principle that does not work very well in the context of supply chain planning. Machine Learning can indeed help to forecast the demand based on learnings from the past. Still, disposing of vast volumes of historical data is, in fact not a must for AI to optimise supply chain planning. The main challenge there is after all the mastering of the complexity and the processing of a multitude of (live) data flows.

According to Davio Larnout, CEO and co-founder of Radix, one of the most common mistakes made by companies that want to implement AI is to first focus on collecting all possible data. They start collecting overloads of data - often even the wrong data or in the wrong formats – and invest their time and energy in something they might never use further. First, you must decide what value you want to create and then start modelling the data accordingly.

“After implementing supply chain planning projects for more than 15 years now, I at least learned

how not to implement supply chain planning”, stated Bram Desmet. Another common mistake is

indeed jumping to technical solutions too fast. The business objectives, ownership and incentives

should be crystal clear first. Gartner's S&OP maturity survey indicated that, on average, the S&OP

maturity is still below 1.0, where it should be at level 3.0 or even 4.0 for any organisation to function correctly since COVID and geopolitical circumstances have complexified the market conditions. When people ask what the business case is for a planning system, Bart refers to the same question about an ERP. The benefits of a planning system are often easier to demonstrate than those of an ERP, while the latter comes with much larger investments. And if you do not do it for your business results, do it for your customers, as they will experience the impact instantly. Create a common understanding throughout your organisation, and use financial metrics to provide insights into how supply chain, strategy and finance are interlinked. Bram often uses his supply chain triangle concept, in which service, cost and cash form the three sides. The Supply Chain Triangle concept captures the idea that as organisations, we deliver different types of service to our customers, which comes at a certain cost and require a certain amount of inventory, or more generically, cash. The triangle is a practical framework to balance service, cost and cash within your organisation and your entire ecosystem. The balancing of these three might be the essence of supply chain management. This, however demands a break through the functional silos of traditional organisations where for instance Sales and Marketing managers are typically on the service side, while Production, Purchasing and partially Supply Chain are pulling on the cost side.

Moreover, most companies operate within complex ecosystems. Being able to cope with and capitalise on the flow of goods and data within these ecosystems has become an essential element of your strategic supply chain management. In delicate supply chains such as those of companies and retailers dealing with fresh goods, this common management or sharing of data can be a vital lever and create a win for all parties involved.

And as indicated by Laurent, the more complex your supply chain becomes, the more added value AI or cognitive automation can bring to your planning. AI can help demystify the complexity and make genuine end-to-end planning possible. Still, you can start small. Create a roadmap to see the bigger picture, and take small steps to ensure you are getting value at each stage. Create, validate, and iterate! And instead of solving all the questions on efficiency, cost gains, cash, and benefits independently, break down the data and functional silos and apply an integrated approach across

your organisation.

"This somewhat sums up our mission," affirms Stijn Devleeschhouwer, Head of Sales & Marketing at Radix. "We are aware of the pressure on the CIO, who is increasingly asked to come up with a (technical) solution to the rising pressure on the supply chain planning team. As always, there is no magic solution. At best, the CIO can get a good understanding of, on the one hand, the business context and the specific challenges we just discussed and, on the other hand, of the latest

technologies - such as AI - that can help design a possible solution. Meetings like this roundtable are a good first step to gaining this knowledge."

Moreover, proper supply chain planning has become a big challenge today as geopolitical tensions are causing unprecedented pressure on the global supply of energy, (raw) materials and technical components. Companies are decreasing their dependencies on too few (global) suppliers and go local, thus making their supply chains less vulnerable but more complex with multiple layers and scenarios.

Moreover, proper supply chain planning has become a big challenge today as geopolitical tensions are causing unprecedented pressure on the global supply of energy, (raw) materials and technical components. Companies are decreasing their dependencies on too few (global) suppliers and go local, thus making their supply chains less vulnerable but more complex with multiple layers and scenarios.-1.png?width=751&height=278&name=BE%20Newsletter%20Content%202022%20(12)-1.png)

Moreover, most companies operate within complex ecosystems. Being able to cope with and capitalise on the flow of goods and data within these ecosystems has become an essential element of your strategic supply chain management. In delicate supply chains such as those of companies and retailers dealing with fresh goods, this common management or sharing of data can be a vital lever and create a win for all parties involved.

Moreover, most companies operate within complex ecosystems. Being able to cope with and capitalise on the flow of goods and data within these ecosystems has become an essential element of your strategic supply chain management. In delicate supply chains such as those of companies and retailers dealing with fresh goods, this common management or sharing of data can be a vital lever and create a win for all parties involved.

No Comments Yet

Let us know what you think